¶ Regarding the inspection of focusing

When encountering thick engraving lines, we consider that it is due to the incorrect setting of the focus. The following aspects can be checked.

¶ 1. Check the material placement plane - whether the honeycomb board is placed correctly.

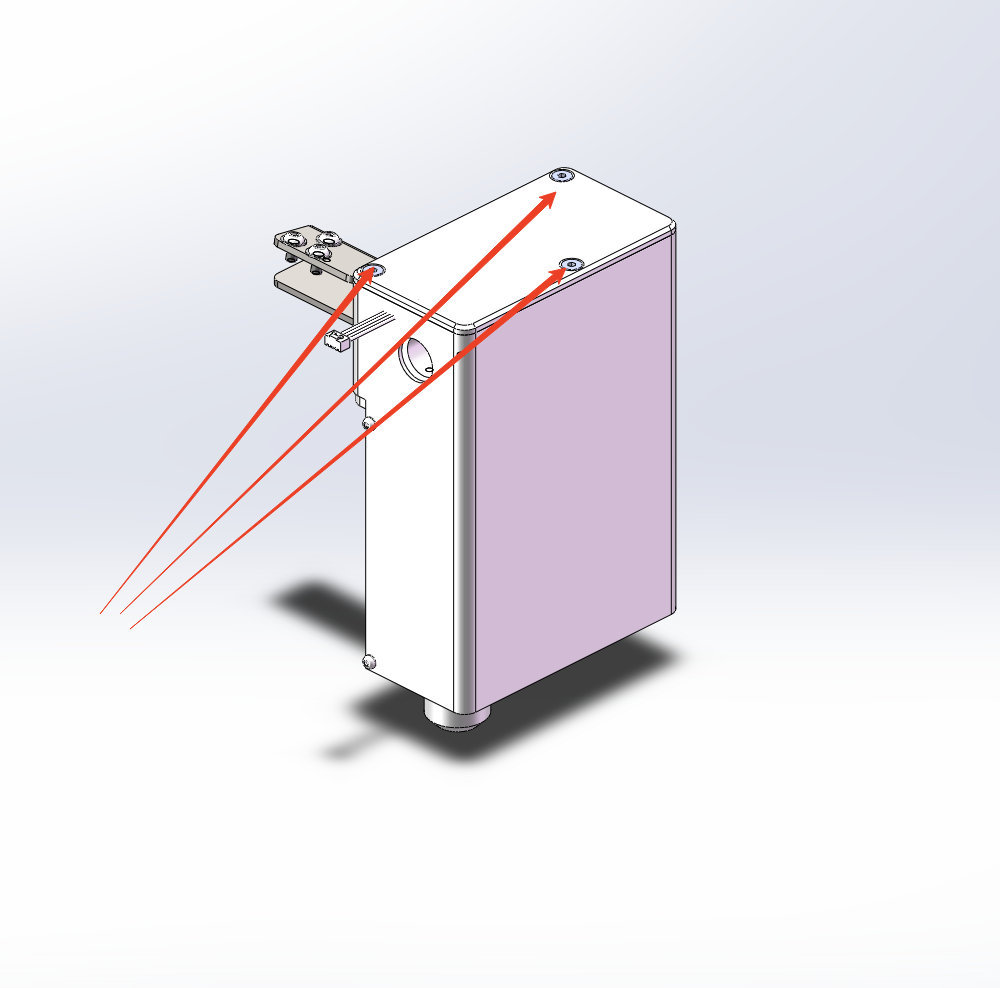

¶ 2.Check whether the optical path is adjusted to the optimal position and whether the red dot can remain in the center position at all positions.

————Calibrate the optical path————

The most ideal situation is that the light target remains at the center at all positions

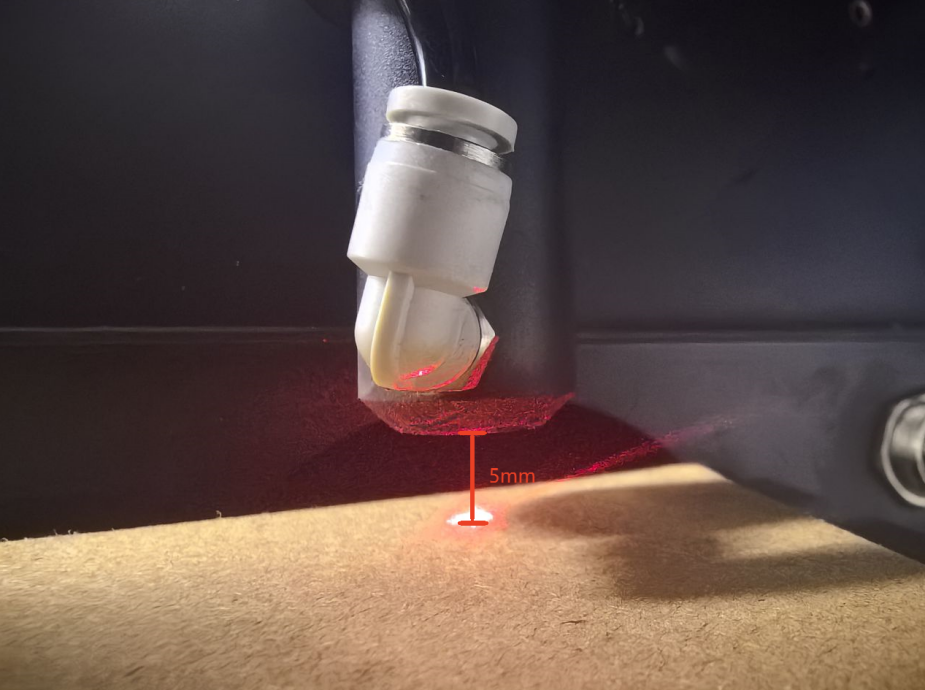

¶ 3. Check whether the Z-axis responds normally and moves to the correct position. The laser head can achieve the optimal working distance when it is 5mm away from the material surface

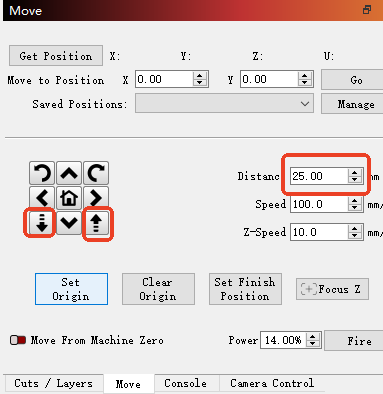

The Z-axis movement can be controlled through Lightburn's console

Verify whether there is any sliding, lagging, jamming or inability to reach the designated position during the Z-axis movement. If it exists, it needs to be opened and adjusted.

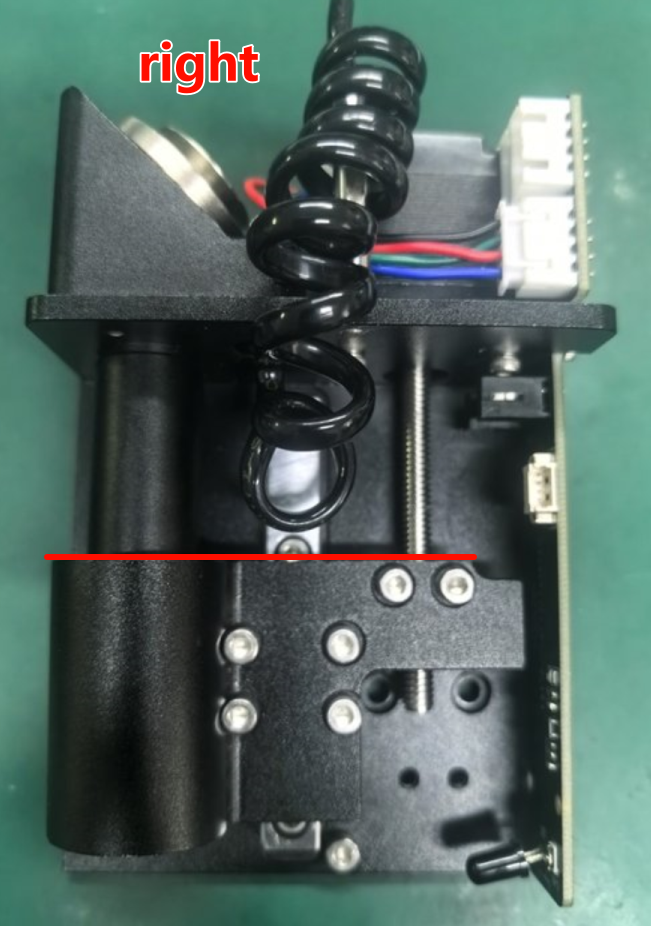

¶ first step:

Open the laser head cover

¶ Step Two:

When the device is turned off, rotate the Z-axis. If it can be turned, rotate the Z-axis to the middle position, then turn on the machine and return it to zero. Repeat this process several times to verify that it is normal.

¶ Step 3:

If it cannot be turned manually, remove the distance sensor

¶ Step 4:

Remove the focusing lens and the air tube

¶ Step 5:

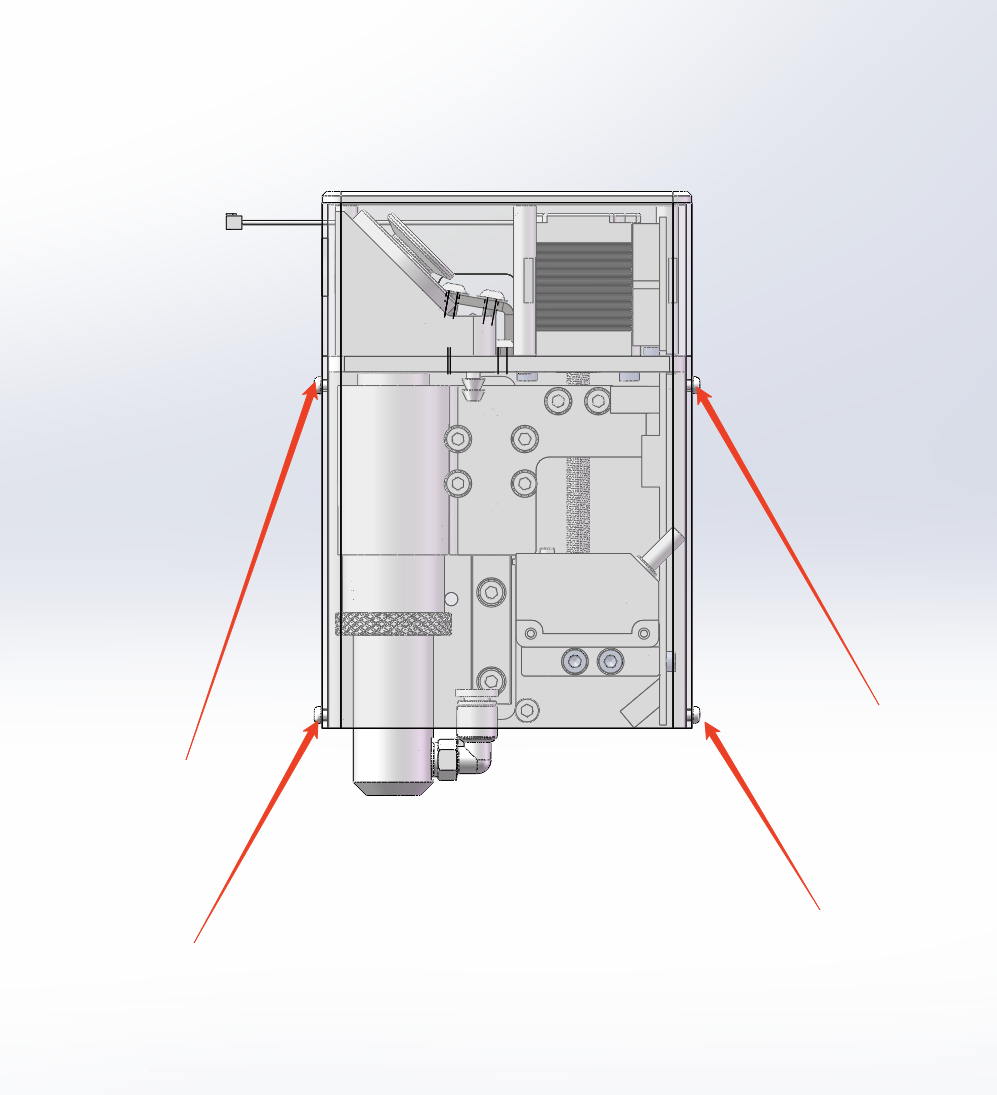

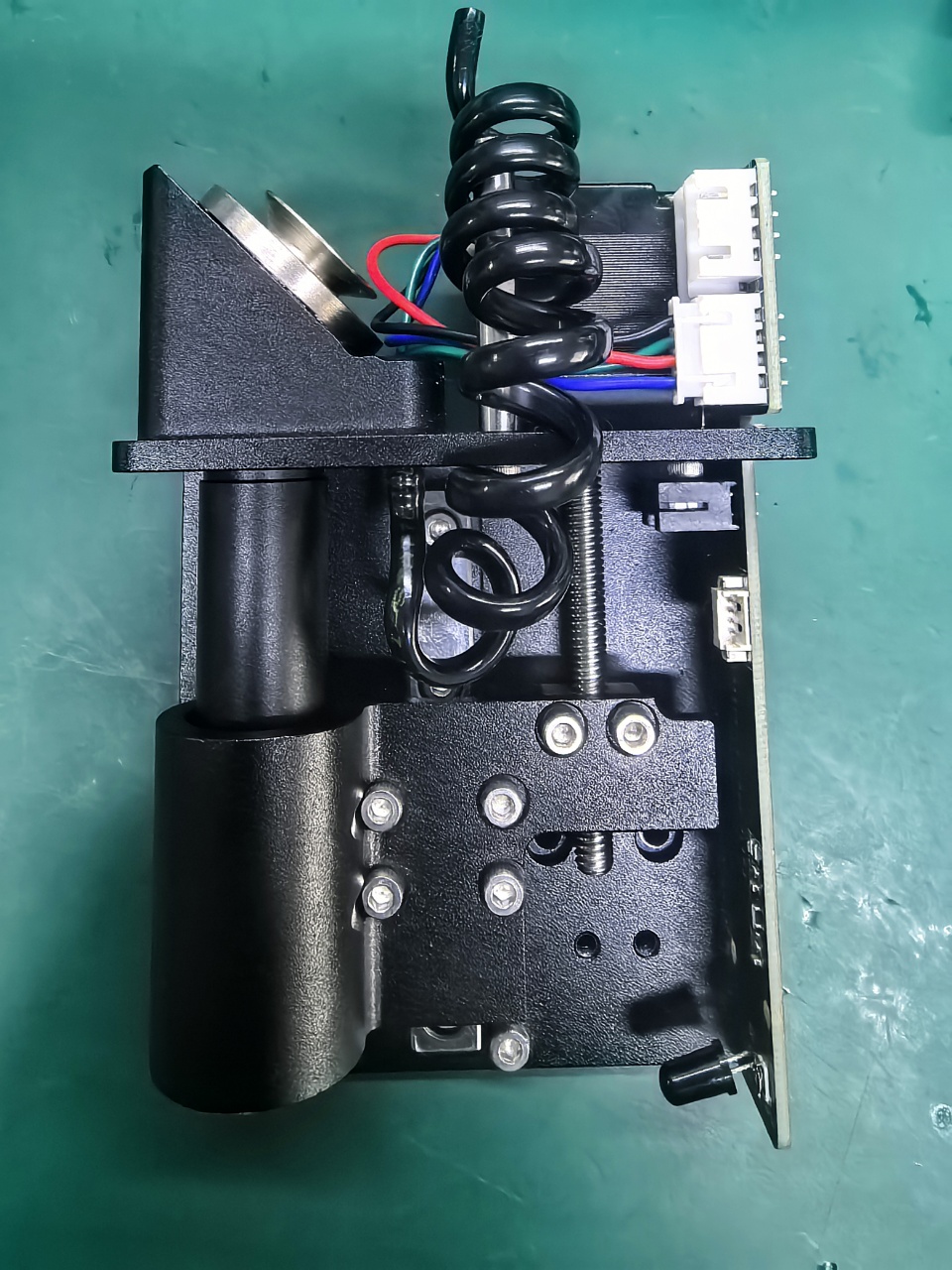

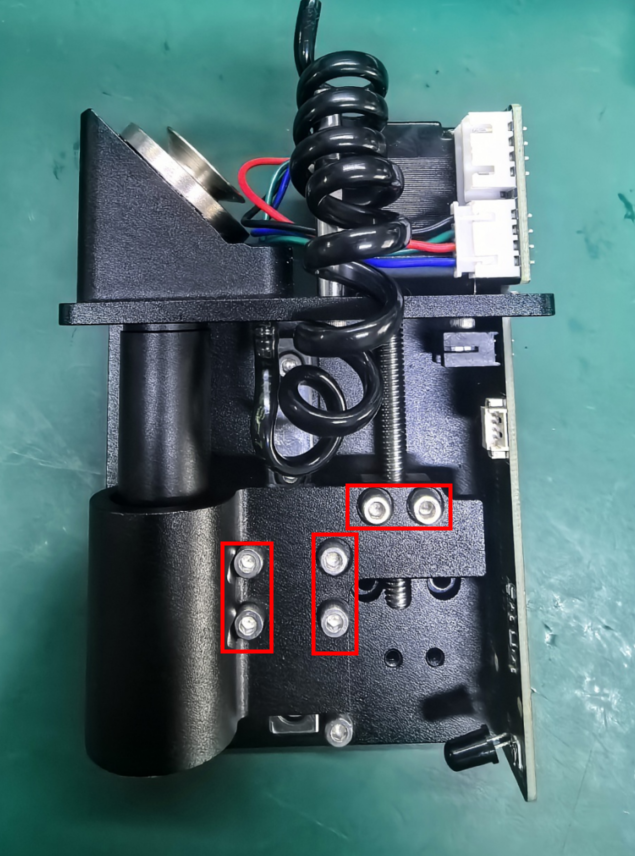

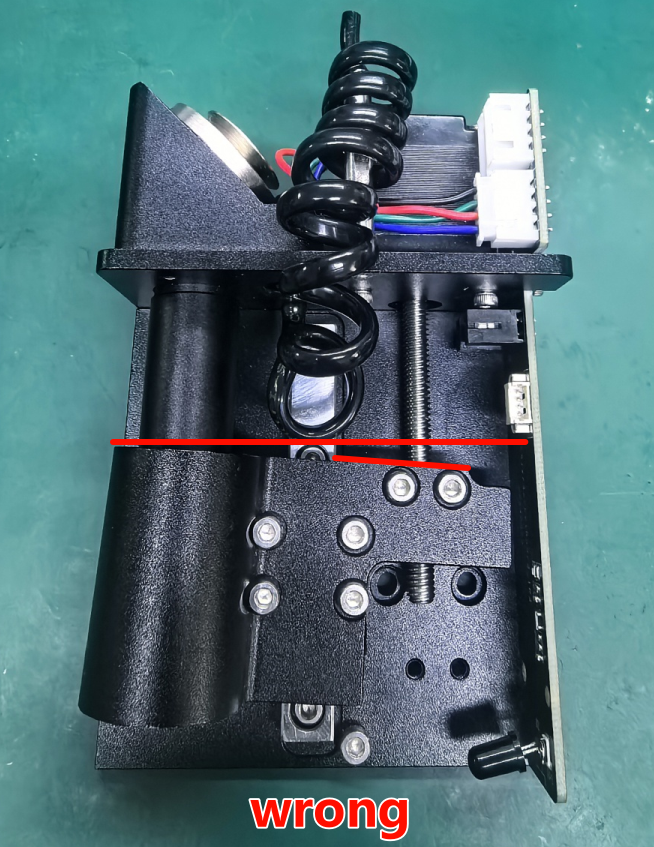

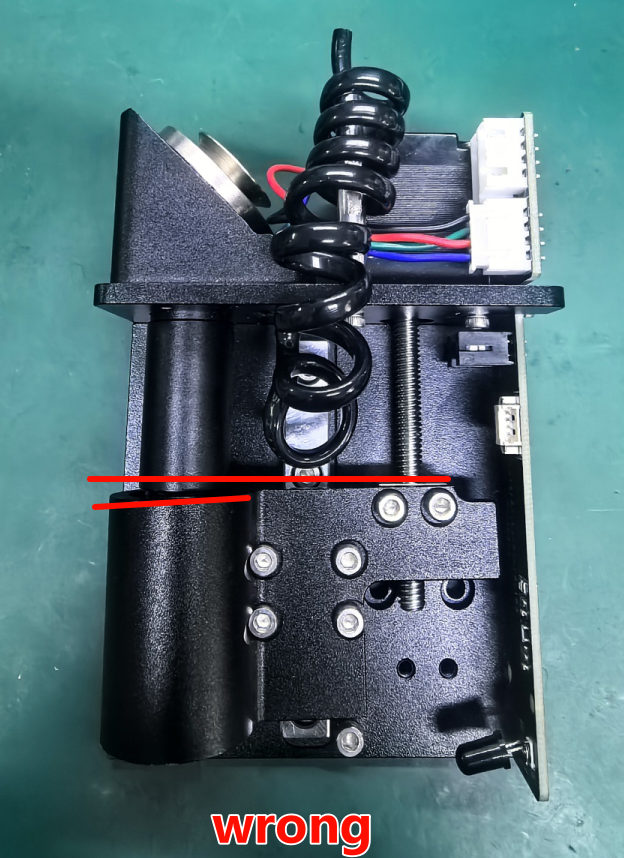

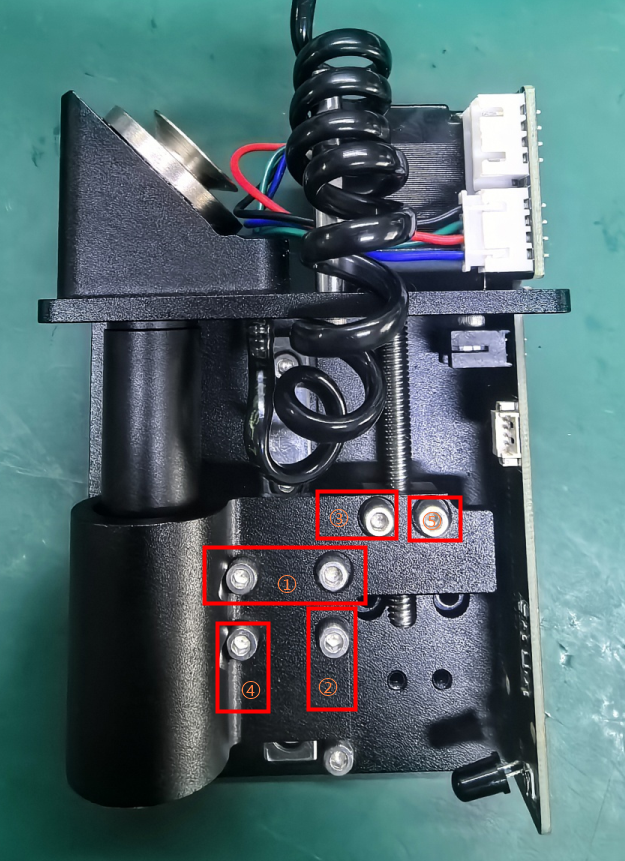

Loosen the screws shown in the picture and adjust the module

¶ Step 6

Tighten the screws in the following order. They do not need to be very tight—just secure enough to prevent movement.

After tightening each screw, click "Return to Zero" to ensure the Z-axis can rotate properly.

¶ Step 7:

Restore the ranging sensor and the metal cover of the laser head. Normal use

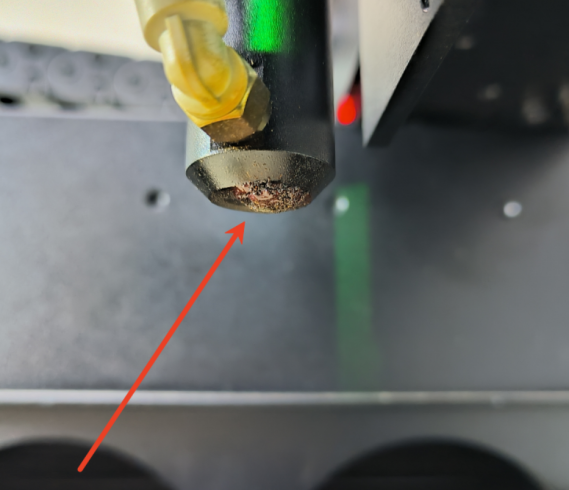

¶ 4. The focusing lens and the air nozzle need to be maintained after long-term use. If they are not cleaned, it will also affect the engraving effect.

It is necessary to open the tube to clean the focusing lens and the air nozzle. You can refer to this link:

Mega Laser Head Cleaning and Maintenance Guide

¶ 5.If you still have any doubts, please contact us.

Support Email: support@monportlaser.com

Mega After-Sales Number: +1 303 210 9328

WhatsApp: https://chat.whatsapp.com/GTTrZQ0FqKv9Ex58vq8ZXw

WhatsApp QR code:

Facebook Official Group: