¶ Mega carving step loss exception

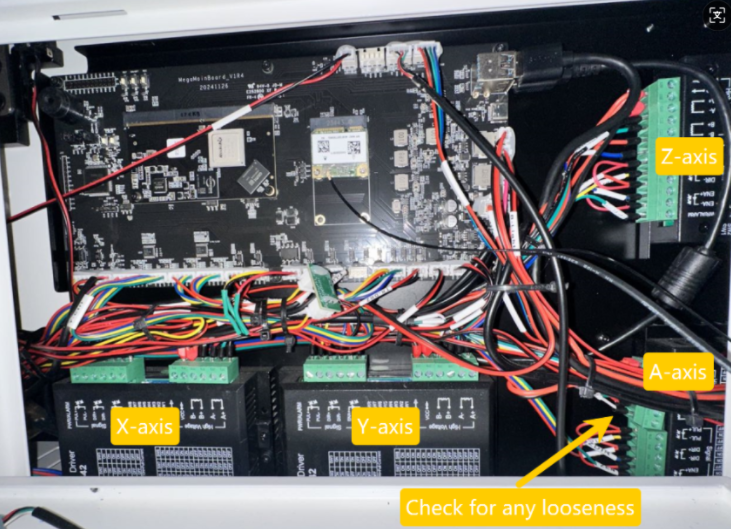

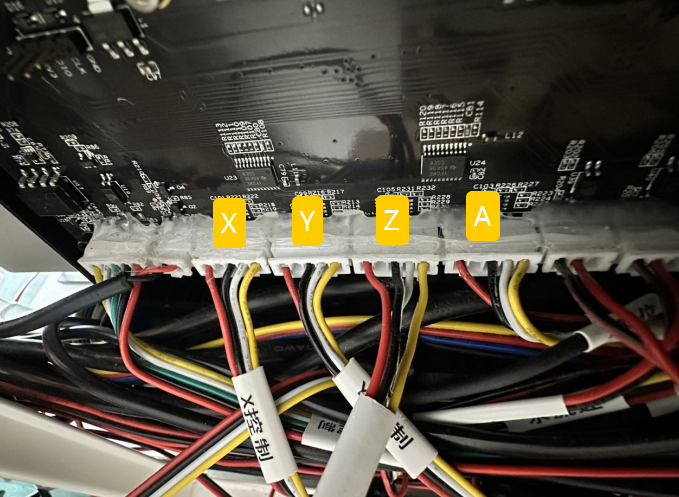

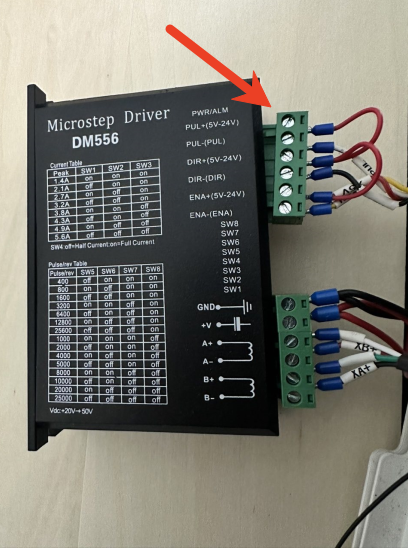

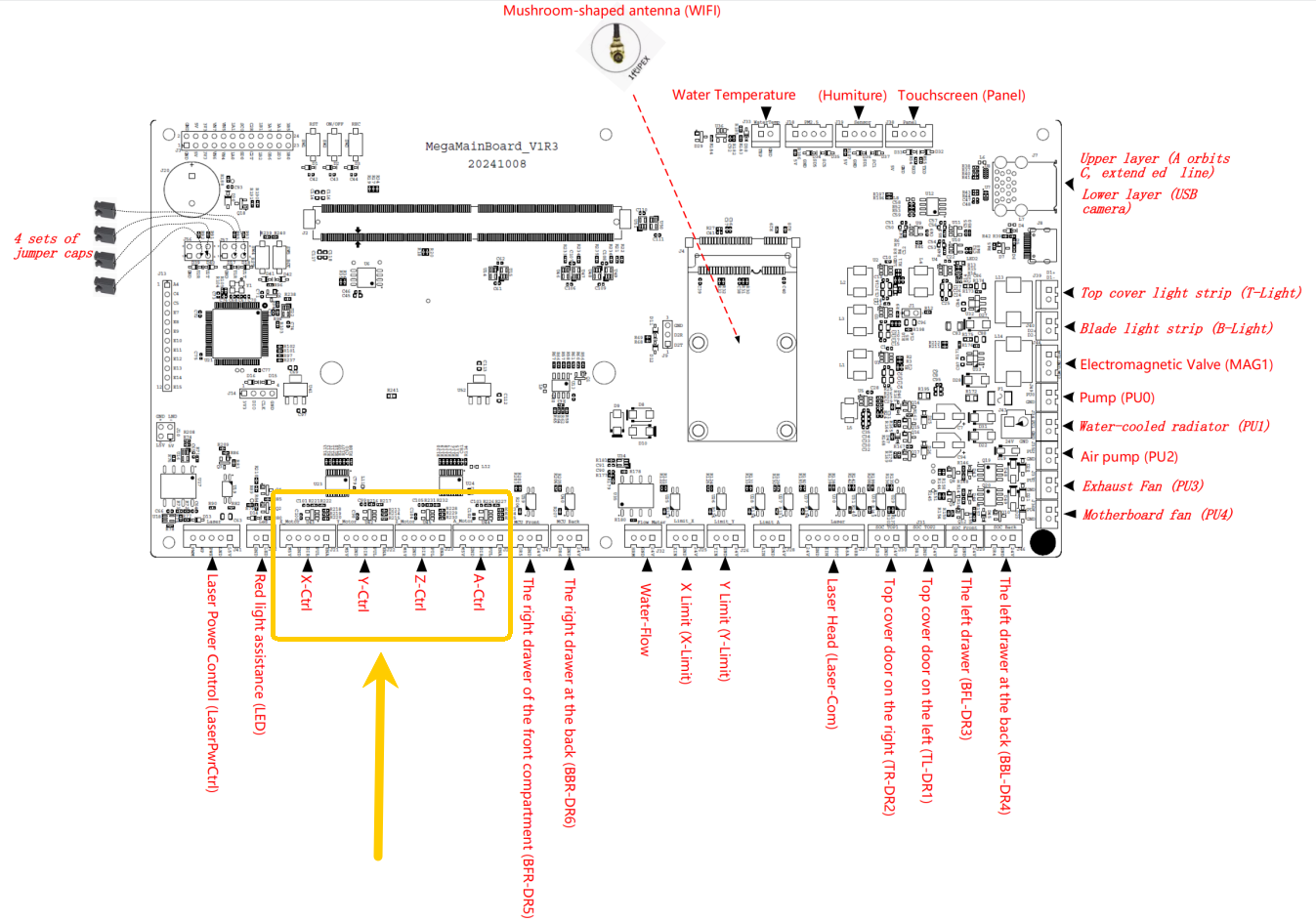

一、Check the X/Y/Z/A axis drivers

1.Open the side cover, revealing the motherboard and the drive.

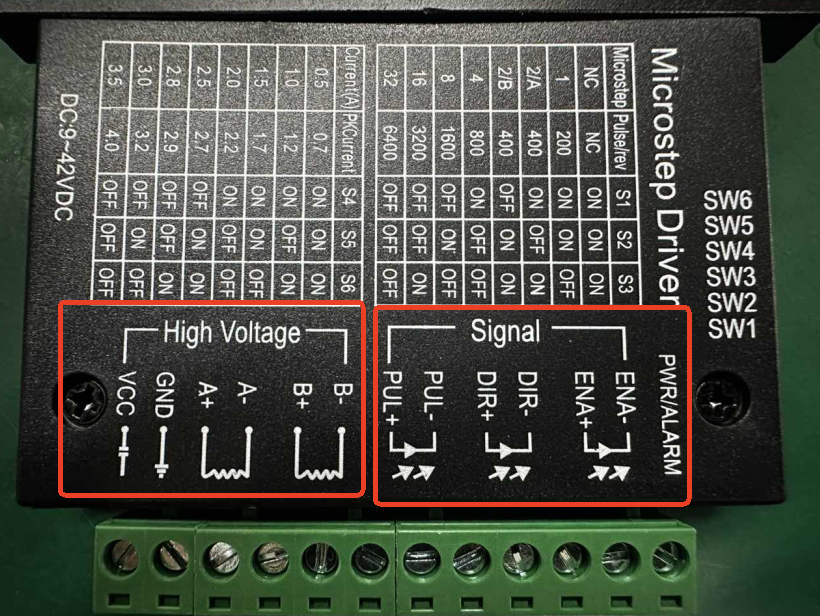

Signal

1.Signal is used to directly transmit information to the motherboard. If during the engraving process the X/Y/Z axes remain stationary without any movement, then you can check whether the interface of Signal is loose or if there is a disconnected line causing poor contact.

High Voltage

2.High Voltage is used to control the X/Y/Z/A axis motors. If there are skipping, deviation, incorrect movement direction or any abnormal lines during the engraving process, please check whether the interface of High Voltage is loose or if the lines are disconnected causing poor contact.

After some steps are missing, shifted, not working, or have incorrect movement directions, there is no obvious loosening or falling phenomenon. However, this still requires you to perform the operation of re-plugging and removing the wires before re-tightening them.

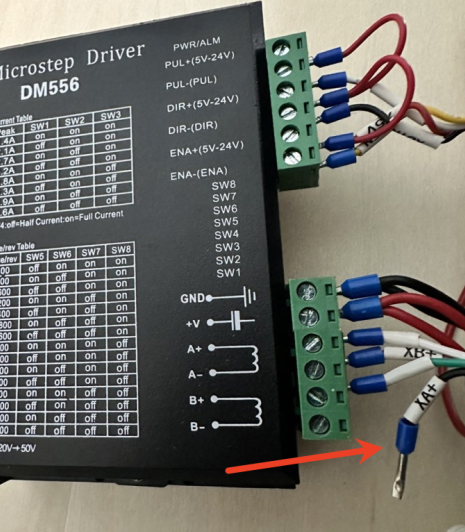

If the terminals become loose, you can simply reinsert them to restore the connection.

If the wiring falls off, you can use a flat-head screwdriver to reconnect the wire.

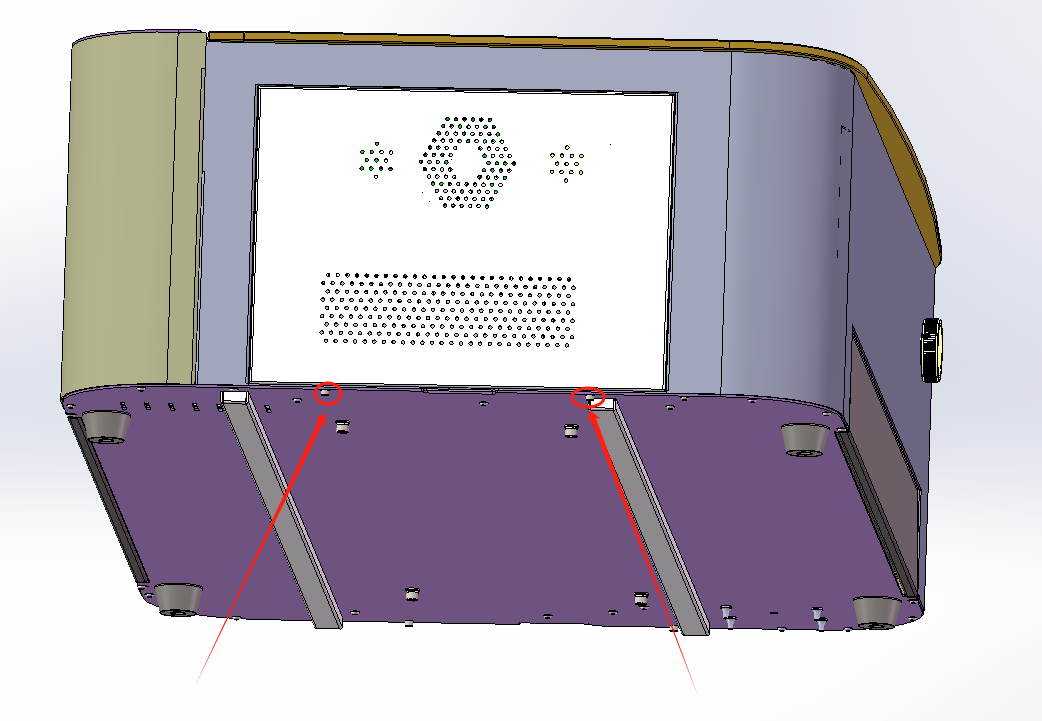

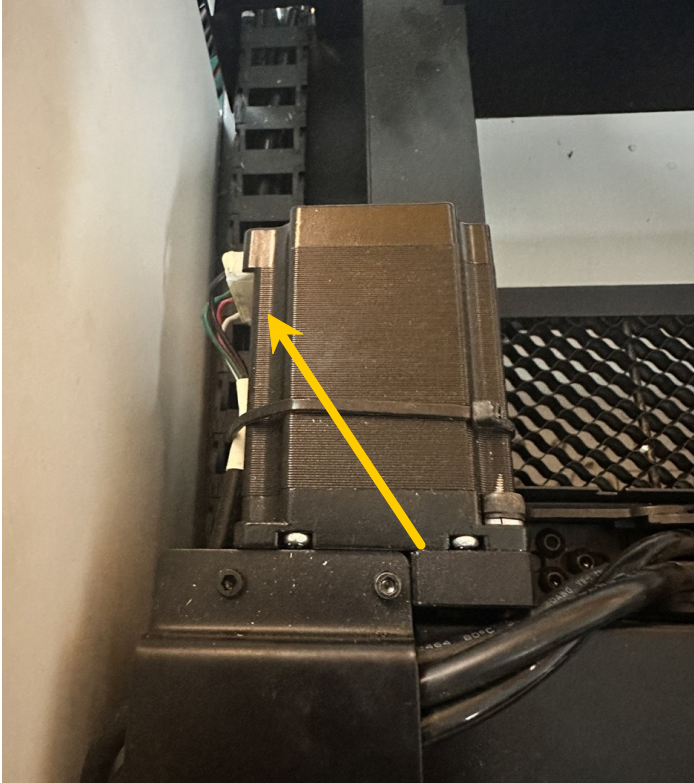

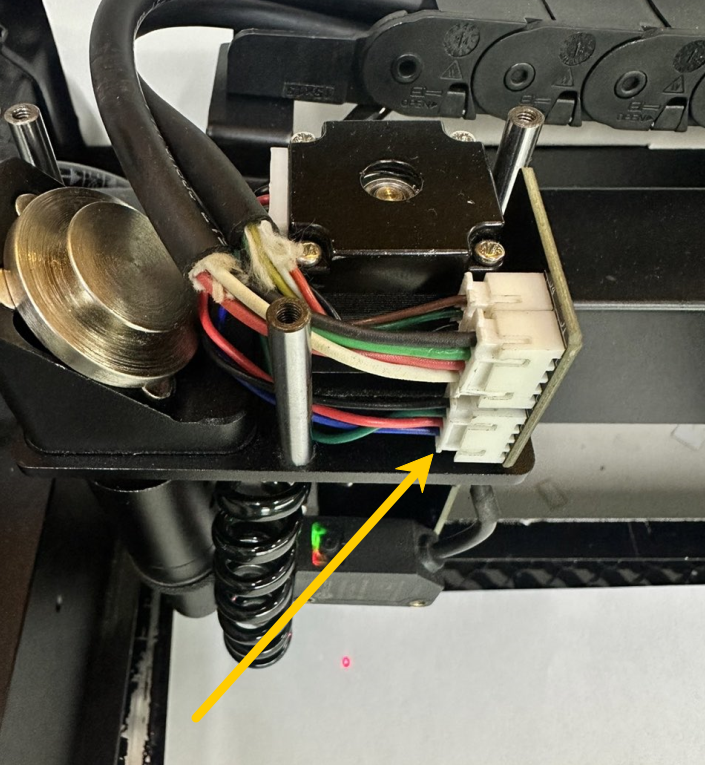

二、Check the motor interfaces of the X/Y/Z/A axes

1.Check whether the terminals of the X/Y/Z/A axis motors are properly disconnected.

三、Check the communication interfaces of the X/Y/Z/A axes on the motherboard

Check if the motherboard interface is loose or not properly plugged in.

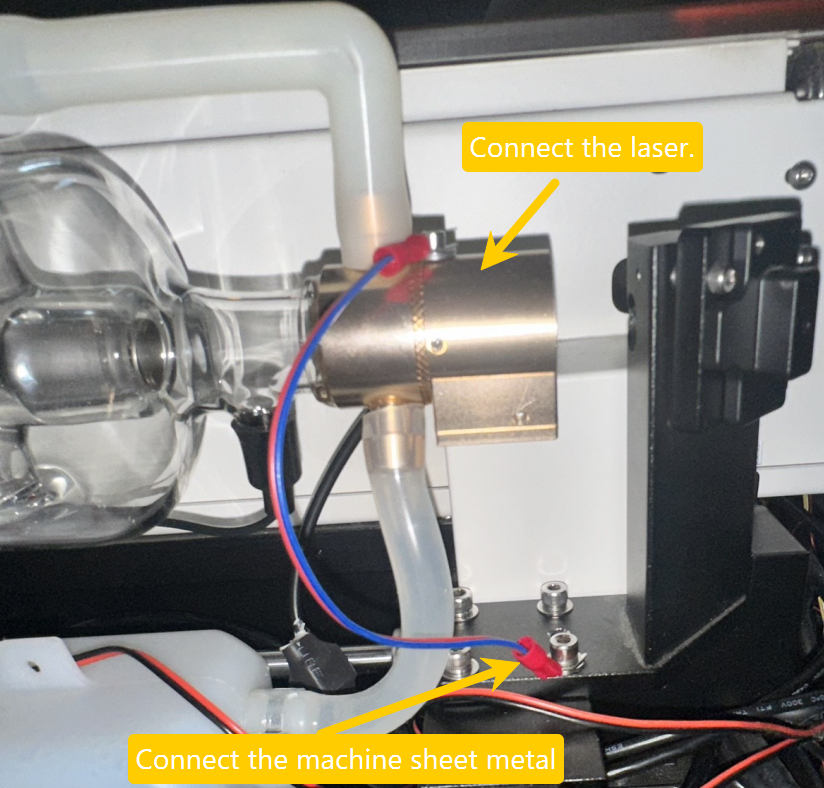

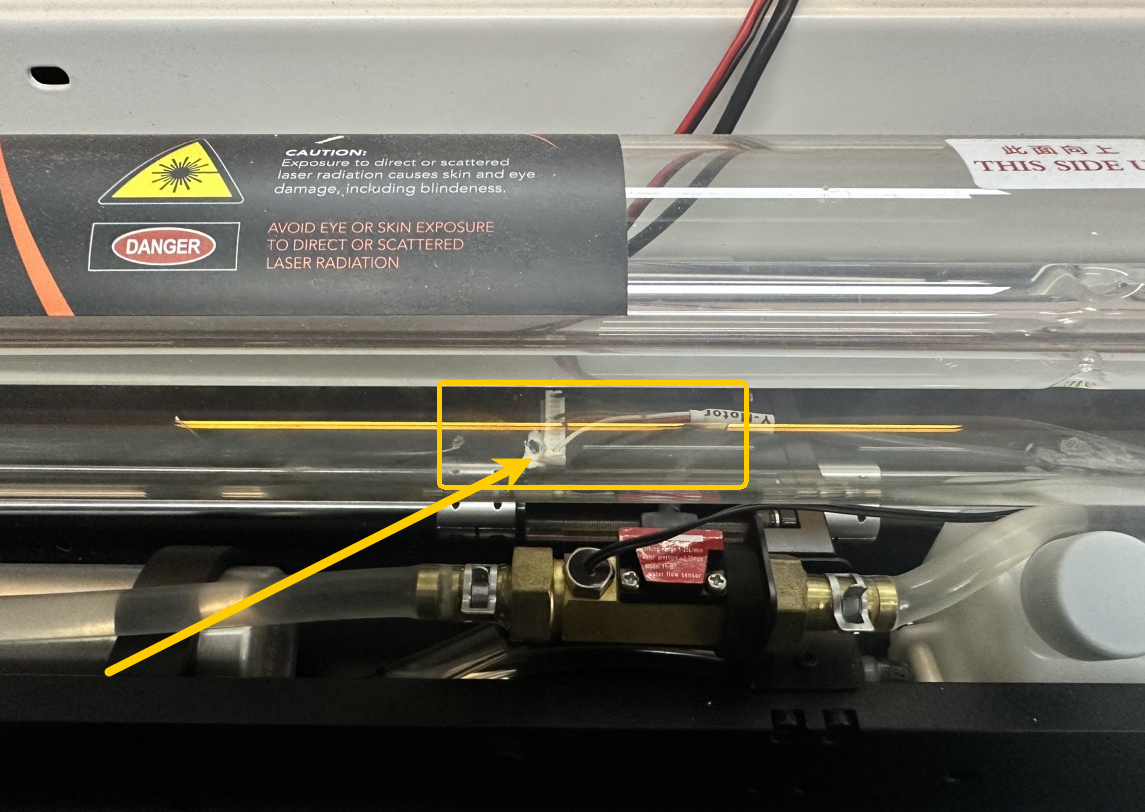

四、Check if the ground wire of the laser tube is functioning properly and eliminate any current interference.