¶ 1. Introduction

This manual is applicable for the maintenance and servicing of MEGA laser engraving machines. It is designed to assist users in operating and maintaining the equipment correctly, ensuring its long-term stable operation and extending its service life. Please read this manual carefully before use and carry out maintenance and servicing strictly in accordance with the operation specifications.

¶ 2. Safety Precautions

- Power-off operation: Before conducting any maintenance or servicing work, please ensure that the power supply is turned off and the power plug is unplugged.

- Wearing protective equipment: When performing maintenance, please wear protective glasses and gloves to avoid laser injuries and mechanical damages.

- Avoid direct contact with laser: The laser beam is harmful to the human body. Do not expose yourself directly to the laser beam.

- Maintain ventilation: During laser engraving, smoke and dust will be generated. Ensure that the working environment is well-ventilated. In necessary cases, use exhaust equipment.

- Fire prevention measures: When laser engraving flammable materials, ensure that there are no flammable substances in the working area and equip with fire extinguishers.

¶ 3. Daily Maintenance

¶ 3.1 Cleaning Equipment

- Outer Shell Cleaning: Use a soft cloth and alcohol to wipe the outer shell of the equipment. Avoid using corrosive cleaners.

- Laser Head Cleaning: Use a soft cloth and alcohol to wipe the light-emitting area of the laser head (due to long-term engraving, stains and oil residues may adhere to the laser head and form lumps, etc.)

- Reflector Mirror: Use a soft cloth and cotton swabs with alcohol to gently wipe the mirror surface. Avoid scratching the coating layer (once a week or adjust according to the usage frequency).

- Focusing Mirror: Use a soft cloth and cotton swabs with alcohol to disassemble and clean after removing the focusing mirror to ensure there are no dust and stains. Pay attention to the marking on the front and back sides. The convex side should face upwards to avoid installing it in the wrong position (suggested once a week).

- Workbench Cleaning: Remove debris and residues on the workbench and keep it flat.

————>Cleaning Equipment Video<————

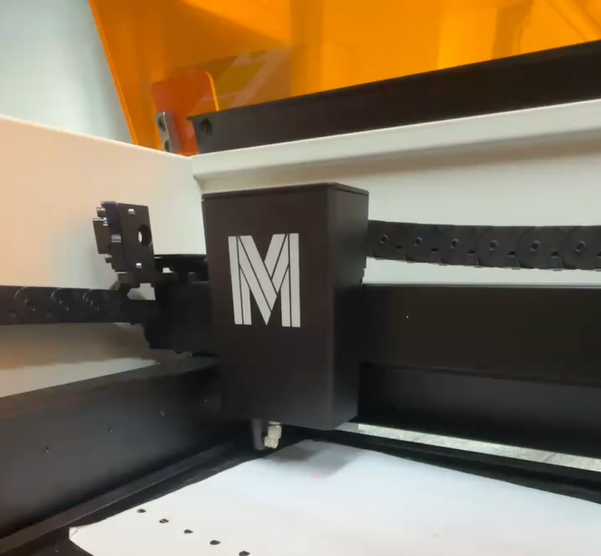

¶ 3.2 Inspection of Laser Head and X-axis

- Laser Head Position: Check whether the laser head is in the correct position and ensure smooth movement of it.

- Laser Head Connection: Check if the connection line of the laser head is loose or damaged.

- Check for X-axis Deviation: Inspect whether the X-axis has deviated due to machine collision or transportation. You can manually adjust the right side of the X-axis, gently tap the right side of the X-axis to make it consistent with the left side.

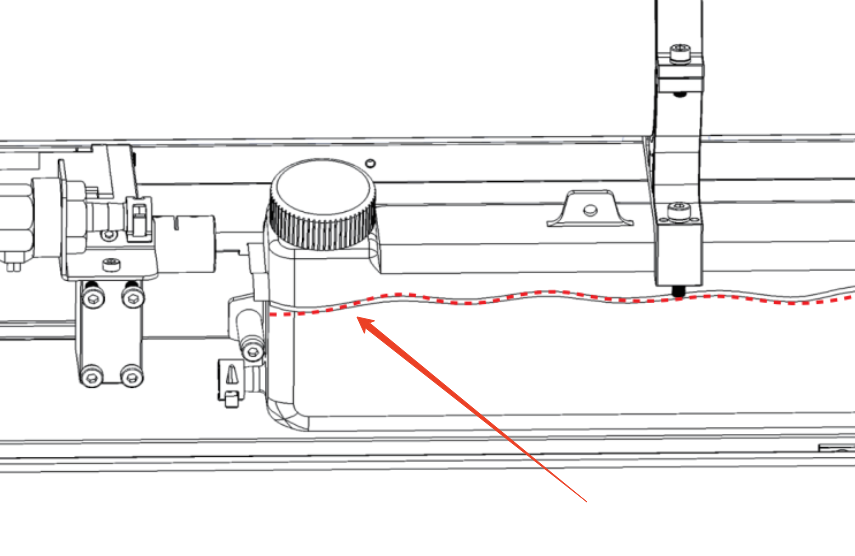

¶ 3.3 Inspect the cooling system

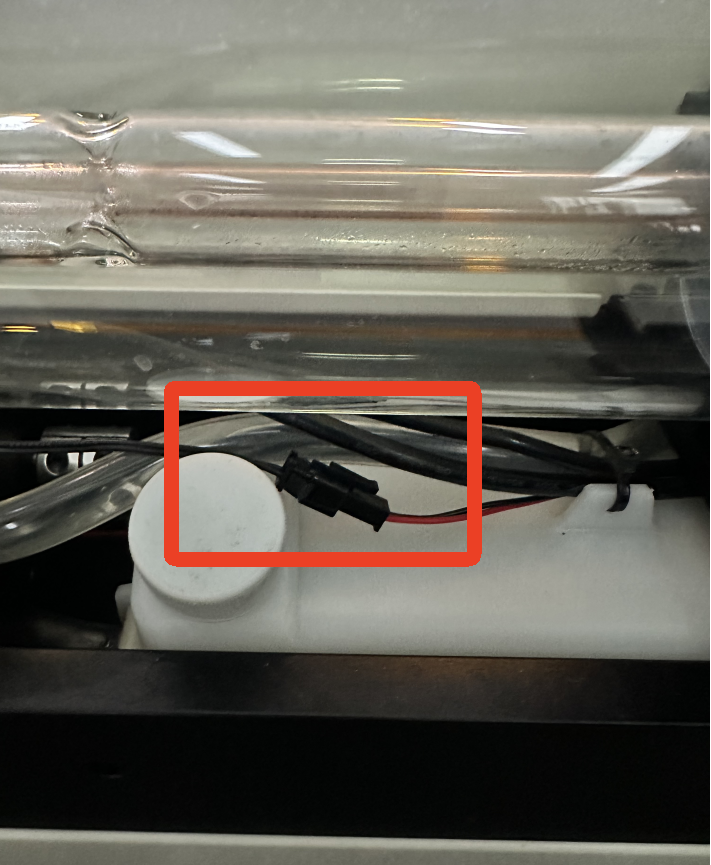

- Coolant: Check the coolant level and ensure it is within the specified range (two-thirds of the radiator). It is recommended to use dedicated coolant.

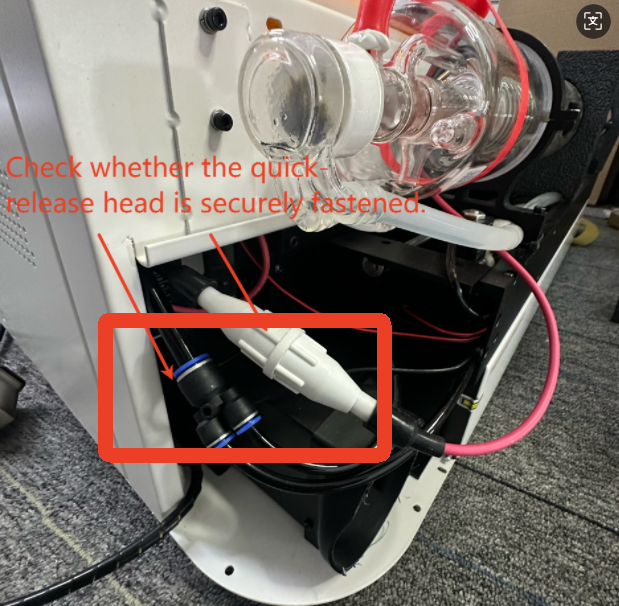

- Operation of the cooling system: After starting the equipment, check whether the cooling system is operating normally and ensure there is no abnormal noise or water leakage.

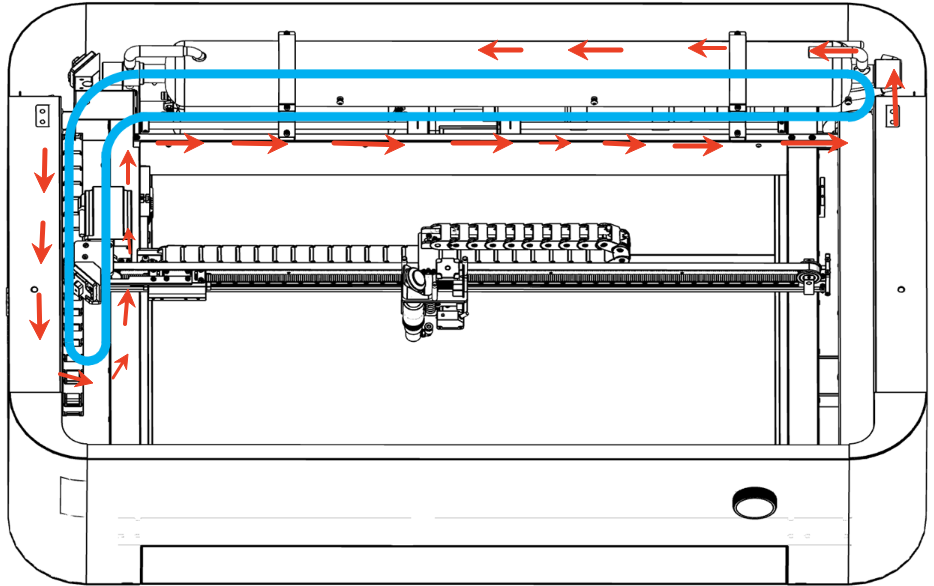

The path of the water-cooled circulation system, as shown in the figure by the blue lines:

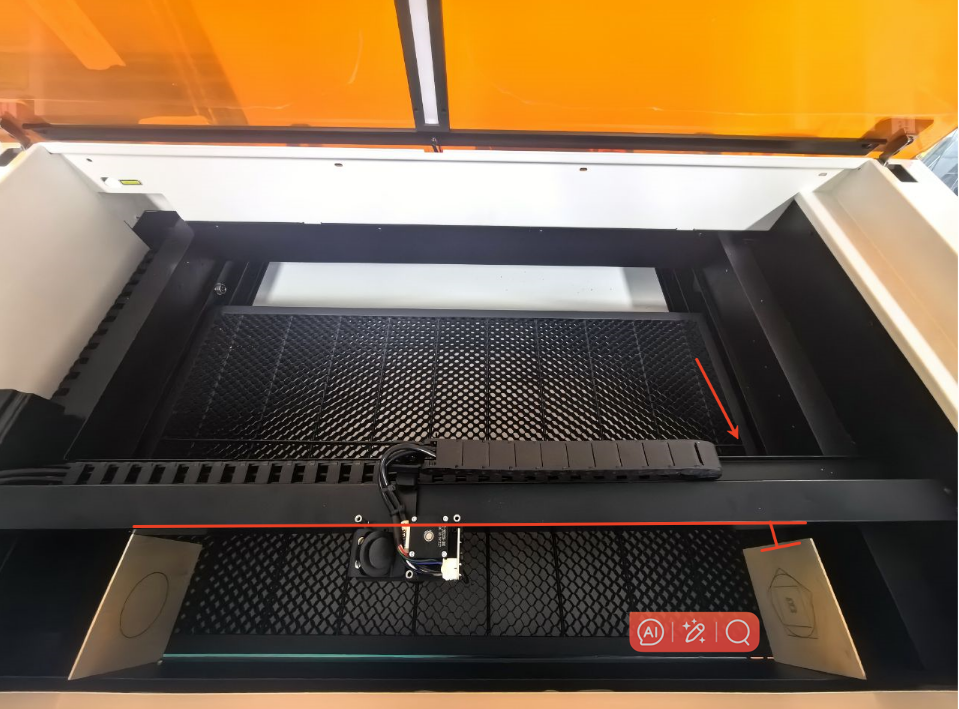

¶ 3.4 Inspection of Smoke Exhaust System

- Smoke Exhaust Duct: Check whether the smoke exhaust duct is unobstructed and free from blockages.

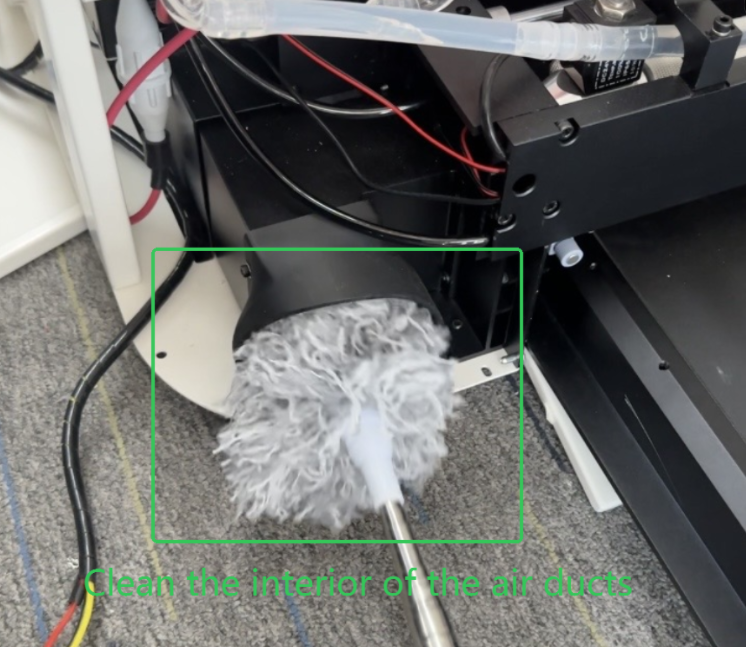

- Smoke Exhaust Fan: Check whether the smoke exhaust fan is operating normally and clean the dust on the fan blades inside the smoke exhaust duct.

¶ 3.5 Check the Laser Light Path

- Light path calibration: Verify the correctness of the light path to ensure that it does not affect the light emission and power.

- Steps: Use paper tape or a red light calibration target to test the center of each reflector's light spot, and adjust it so that the laser is incident perpendicularly to the focus mirror center (this must be done every 3 months or after replacing or cleaning the lens).

————Calibrate the optical path————

¶ 3.6 Electrical Inspection

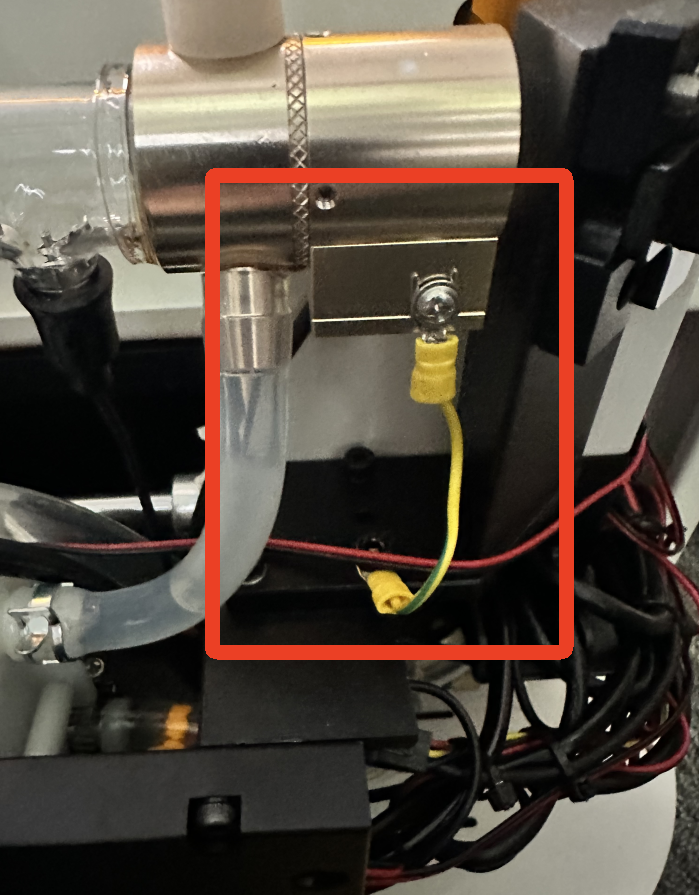

- Power cord/Grounding: Avoid loosening or oxidation (once every six months).

- High-voltage cable: Check if the insulation layer is aging (especially for the power supply cable for laser tubes).

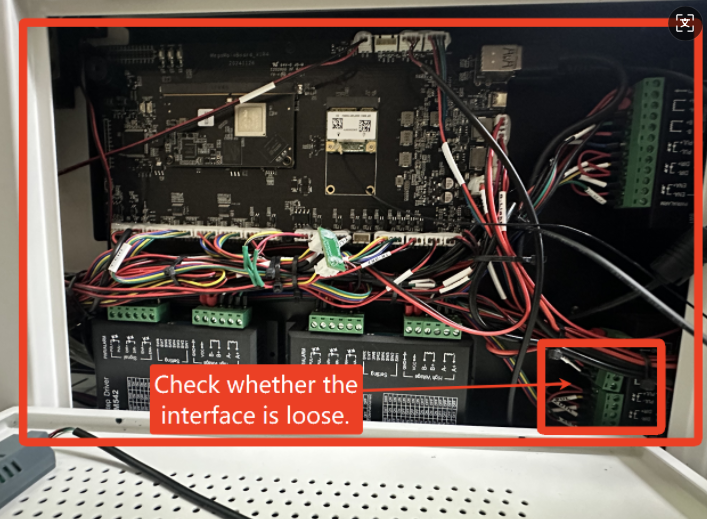

- Board connections: Check if the terminals of each component are securely plugged in to avoid poor contact.

¶ 4. Regular in-depth maintenance

¶ 4.1 Monthly Maintenance

- Guide rail lubrication: Apply the dedicated lubricant to the guide rails to ensure smooth operation.

- Optical system inspection: Examine the conditions of the reflecting mirror and focusing mirror, and clean or replace them if required.

- Electrical system inspection: Check the electrical connections for firmness to ensure no looseness or aging.

¶ 4.2 Quarterly Maintenance

- Laser tube inspection: Check the working condition of the laser tube to ensure its output power is normal. If the laser tube is aging or its power is decreasing, it should be replaced in time.

- Cooling system cleaning: Clean the water tank and pipes of the cooling system to prevent the accumulation of scale and impurities.

- Exhaust system cleaning: Clean the exhaust pipes and fans to ensure good exhaust effect.

¶ 4.3 Annual Maintenance

- Comprehensive Inspection: Conduct a thorough inspection of the equipment, covering mechanical, optical and electrical systems.

- Replacement of Wearable Parts: Replace wearable parts such as belts, bearings, and sealing rings based on the usage conditions of the equipment.

- Calibration of Equipment: Calibrate the equipment to ensure its accuracy and stability.

¶ 5. Common Questions and Solutions

¶ 5.1 Laser Power Decline

- Possible Causes: Aging of the laser tube, dirtiness of the lens, deviation of the optical path, malfunction of the cooling system.

- Solutions: Replace the laser tube, clean the lens, re-adjust the optical path, inspect the cooling system.

¶ 5.2 Engraving Accuracy Decline

- Possible Causes: Insufficient lubrication of the guide rail, loose belt, deviation of the laser head position.

- Solutions: Lubricate the guide rail, adjust the belt, calibrate the position of the laser head.

¶ 5.3 The equipment fails to start

- Possible causes: Power failure, loose electrical connection, control system malfunction.

- Solutions: Check the power supply, tighten the electrical connection, contact professional maintenance personnel.

¶ 5.4 Abnormal cooling system

- Possible causes: Insufficient coolant, faulty water pump, blocked pipes.

- Solutions: Add coolant, check the water pump, clean the pipes.

¶ 5.5 Poor exhaust smoke effect

- Possible causes: Blocked exhaust smoke pipes, faulty fan.

- Solutions: Clean the exhaust smoke pipes, check the operation status of the fan.