¶ OVERVIEW

The Batch Fill feature is designed for smart and efficient production. Built on advanced vision algorithms, the Batch Fill function enables MDH to recognize materials that are similar to samples, locate them, and create identical designs for them. It simplifies the process of design adjustment, making your production more efficient and easier.

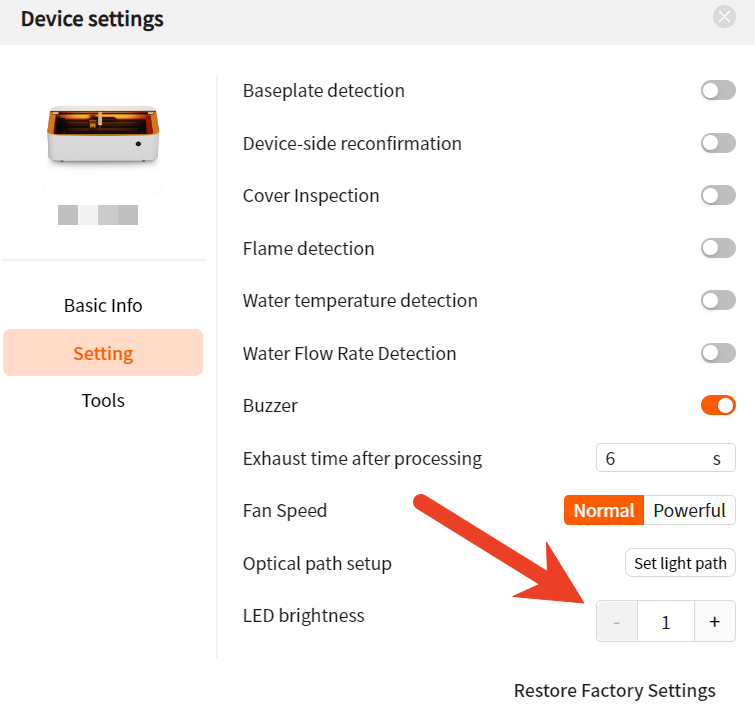

Before carving, please adjust the light intensity to level 1.

(Excessive brightness will cause the material to reflect light, which will affect the recognition effect. It is recommended to use the 1st gear of the light.)

¶ Steps

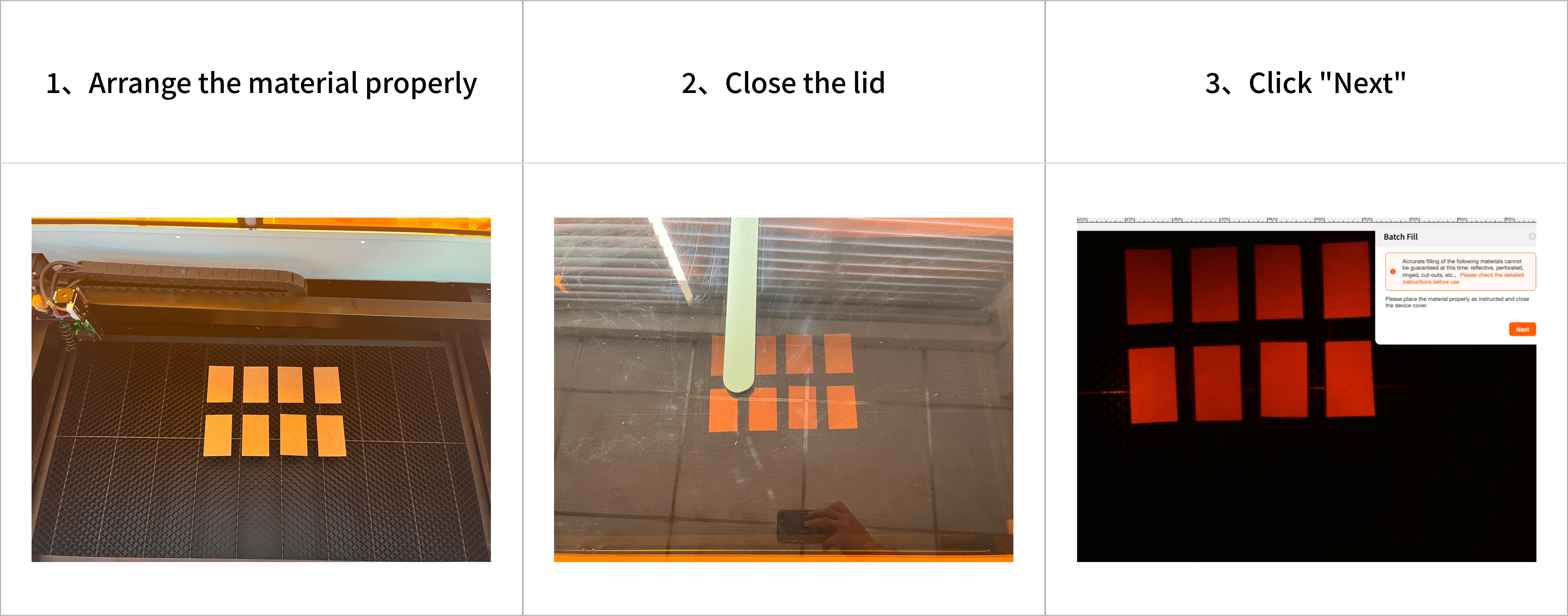

¶ Step 1

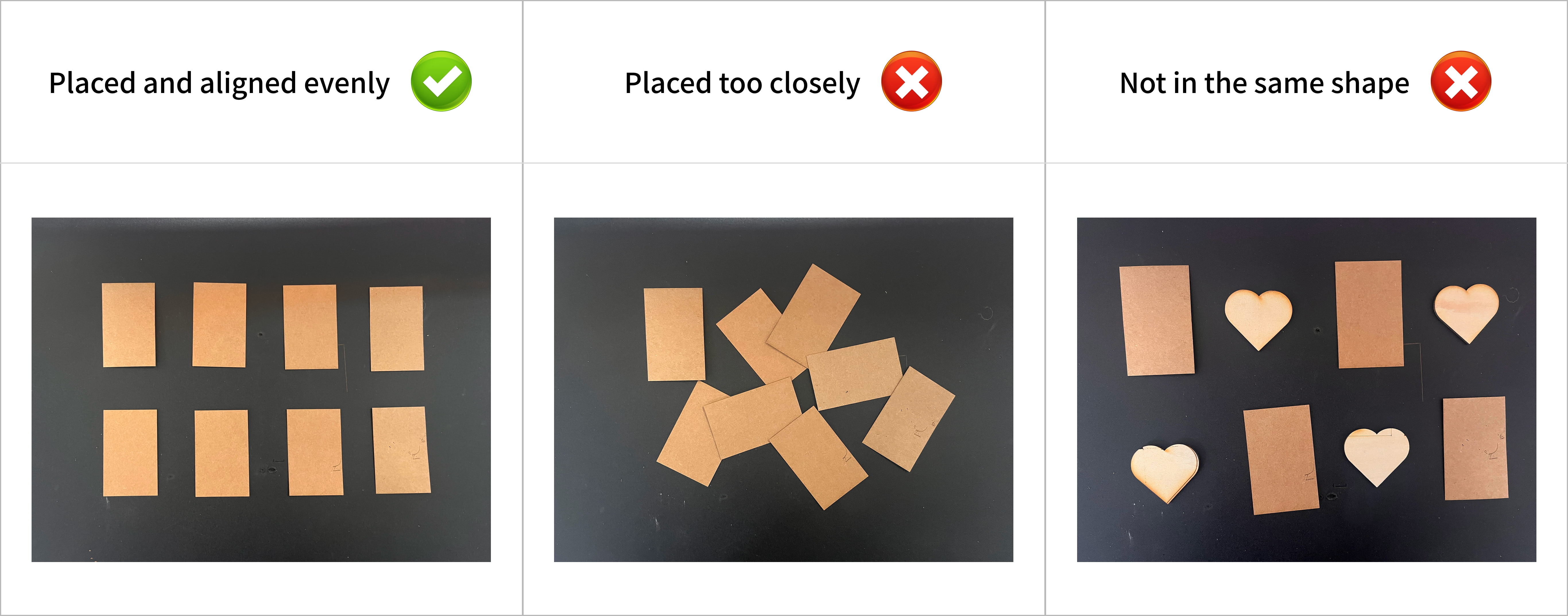

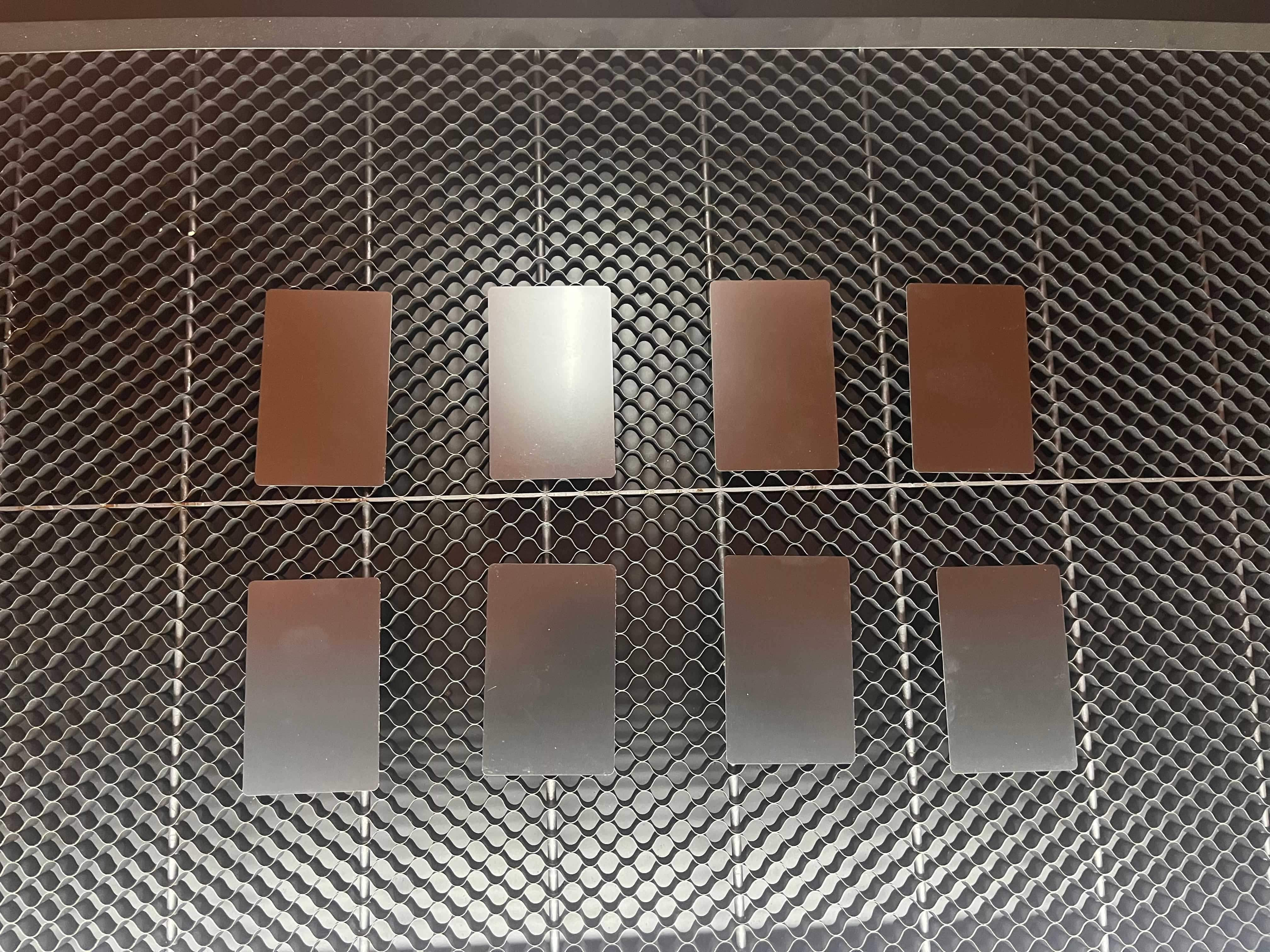

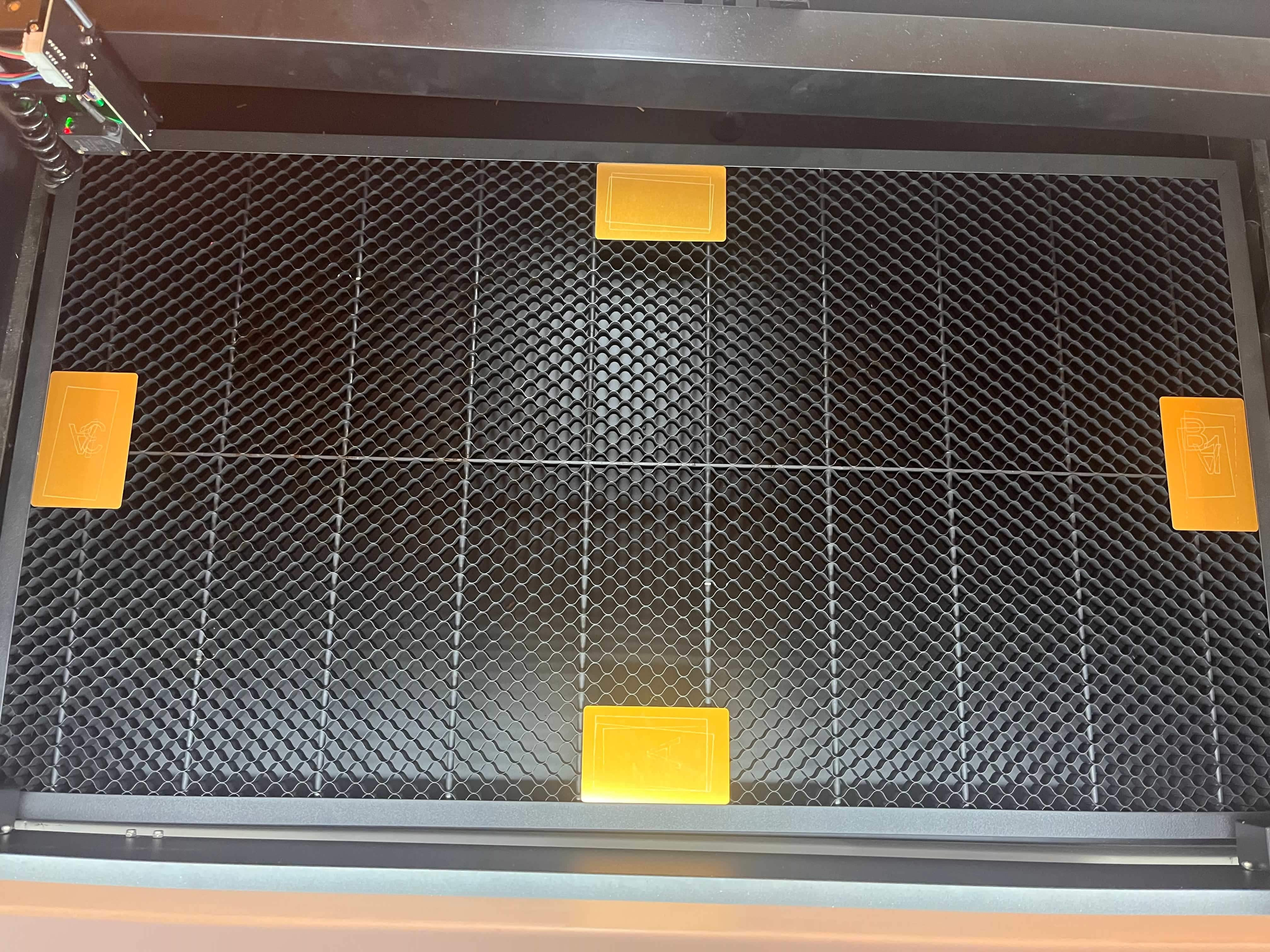

Place materials of the same size, color and shape in the middle of the honeycomb board. The distance between each piece of material should be more than 2 millimeters, and they should be evenly placed and aligned.

* Note: Please place the material in the middle. If the subject to be photographed is outside the camera's shooting range, the camera will be unable to capture it and thus cannot process it either.

¶ Step 2

Place the material inside the machine.Close the lid.Click "Next".

¶ Step 3

Place the material, select the elements, and do a smart fill.

¶ Troubleshooting Material Recognition Failure (Possible Causes and Solutions)

Possible Cause 1: The base plate is dirty or scratched, resulting in inaccurate material recognition.

Solution: Check and clean the backing plate. Use black tape or ink to cover the scratches to get a black base plate.

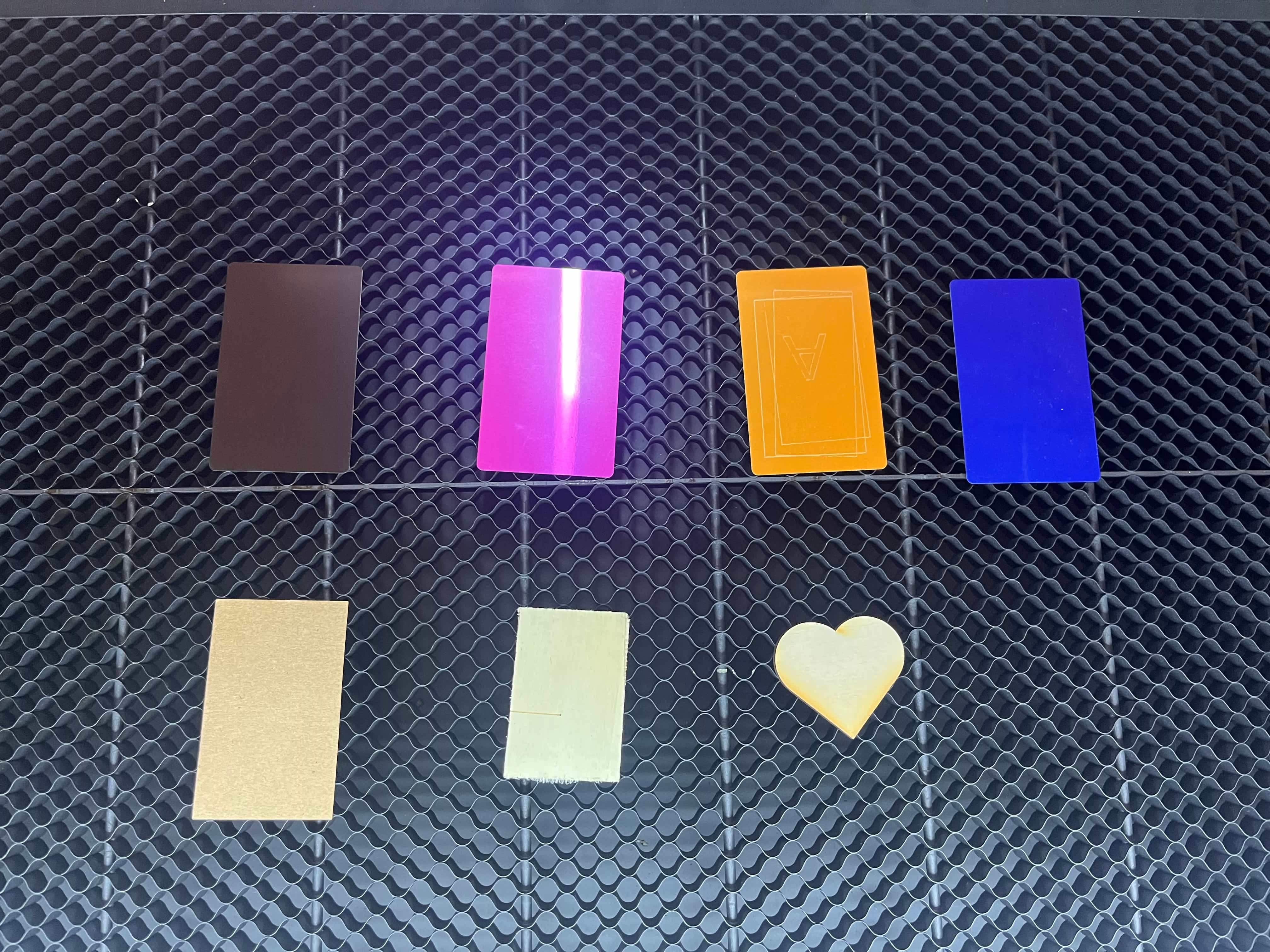

Possible Cause 2: The color of the material is too similar to the color of the backing plate, or the material reflects some light, causing the algorithm to not work.

Solution: Apply white water-soluble paint to the material before processing.

Possible Cause 3: Camera lens is dirty, resulting in blurred or overexposed images.

Solution: Clean the camera lens with a cotton swab moistened with alcohol.

Possible Cause 4: The material is not of the same color, size, thickness or texture.

Solution: Sort materials into different types and process one type at a time.

Possible Cause 5: Material is not placed properly, e.g. some of it is placed too close to the edge of the base plate.

Solution: Place the material in the center area of the base plate.

Possible Cause 6: No element is placed on the material.

Solution: Place an object on the material, edit it, select it, and choose Fill (Application Batch Fill).

Possible Cause 7: Fill objects on materials with holes or rings.

Solution: Use regular materials for filling.

¶ Frequently Asked Questions

¶ 1. How long does it take to complete the fill?

Typically, the fill is completed within 10 seconds.

¶ 2. Are there any special requirements for using the Batch Fill feature?

Yes.

● You need to use a clean substrate without scratches so that the software can accurately recognize the material with the camera.

● You need to measure the thickness of the material before batch filling to ensure greater filling accuracy.

¶ 3. Where do I place the material so that the camera can capture it more clearly?

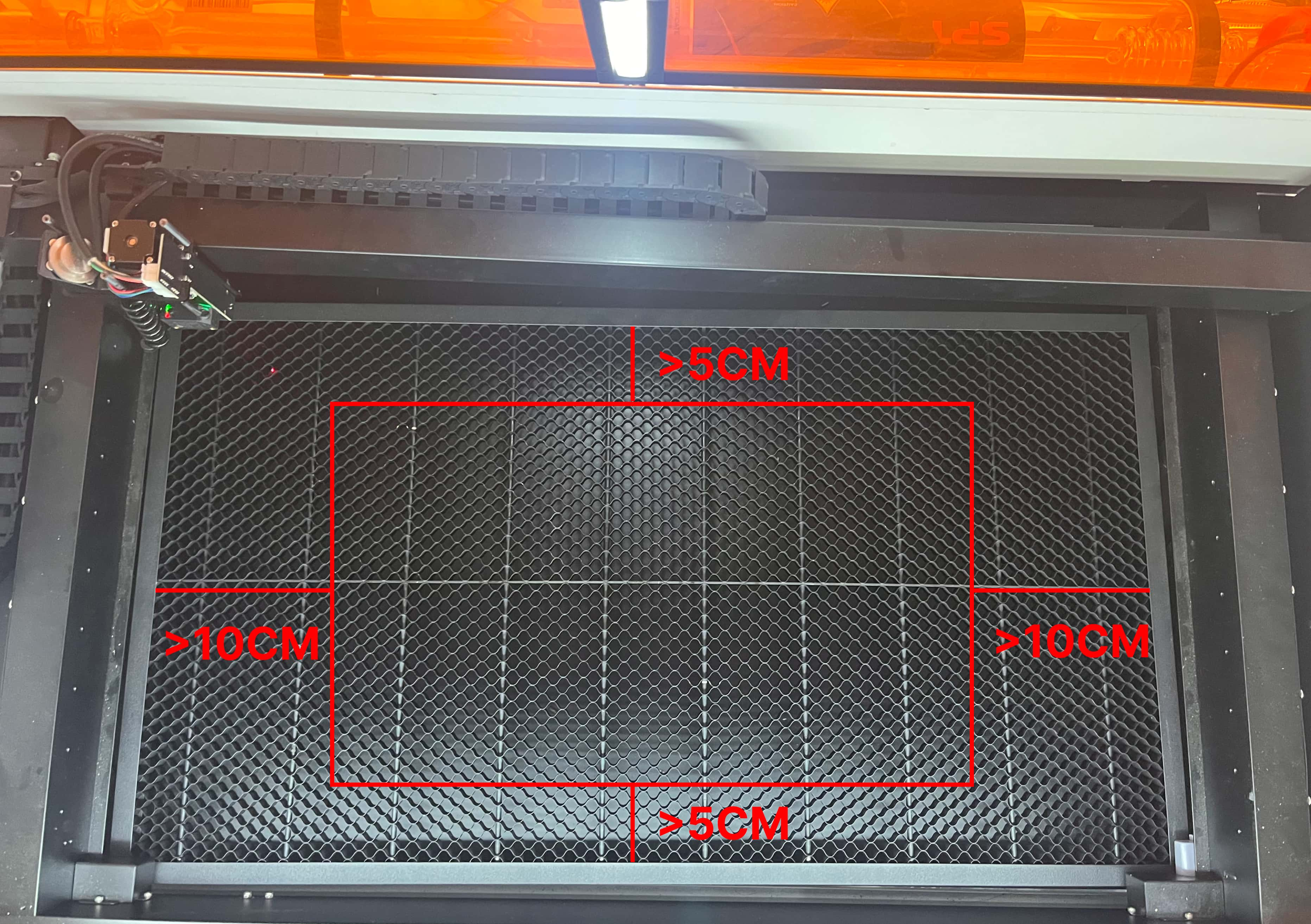

● Place the material in the center of the base plate, evenly aligned with an angle difference of less than 10 degrees.

● It is recommended that the material be placed in a center area that is 5 cm or more from the back, 5 cm or more from the front, and 10 cm or more from the left and right sides.

*Note: If a material is placed outside the camera's capture area, the camera cannot capture the material and therefore cannot process it.

¶ 4. What are the material requirements?

● Thickness: The Batch Fill function supports flat materials up to 4 mm thick. Thicker materials may not be recognized due to the protrusion of some parts. The material needs to be flat. Curved surfaces may not be accurately recognized.

● Color: The color of the material can be distinguished from the color of the backing and the material does not reflect light. If the color of the material is too similar to the color of the background, the edges of the material may not be recognized. Reflected light may interfere with material recognition and cause recognition to fail.

● Size: Materials from 2 cm to 20 cm in length are supported. If the material is too small, it may not be recognized; if it is too large, it may exceed the processing area and the camera may not be able to capture it.

● Texture: Materials need to have a similar texture. Differences between texture, color, reflectivity, and exposure may cause recognition to fail. For example, cracks or missing parts of the material may result in non-recognition.

● Shape: For materials with holes, rings, and other structures, pay attention to illumination. Ensure that key features are clear and recognizable.

● Placement: You need to place the materials in the center of the base plate, with a distance of more than 2 mm between each material.

● Quantity: Do not place too many materials at once. Keep the number below 20.

● Attributes: Currently, materials that may be deformed are not supported.